You want a Truckee remodeler who builds to 200 psf snow loads, meets Title 24 and WUI, and manages permits, inspections, and TRPA clearances without surprises. We deliver airtight, high-R envelopes, cold-climate heat pumps, and ENERGY STAR windows to stop ice dams and cut bills. Our design-build process locks scope, schedule, and budget with room-by-room estimates, blower-door verification, and QA checklists. Licensed, insured, and local-so your home performs in every season. This is what that means for you.

Essential Highlights

- Regional code professionals: Title 24 regulations, Truckee amendments, WUI defensible space standards, and comprehensive permitting/inspection sequencing handled in-house.

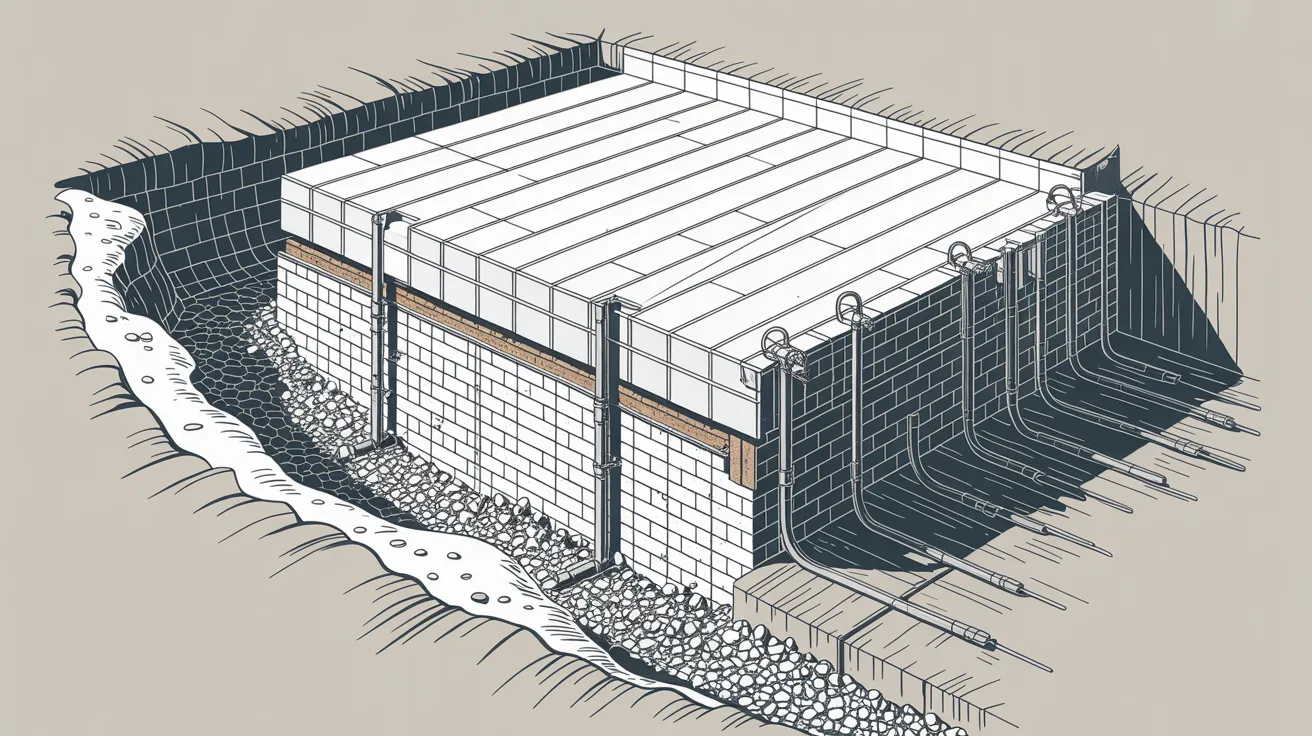

- Mountain-optimized builds: winter load framing, ice barrier systems, properly ventilated ventilation, and weatherproof foundations.

- Envelope performance: R-60+ attics, airtight detailing, blower-door tested, ENERGY STAR Northern windows with AAMA-certified flashing.

- Open delivery: dedicated project manager, constructability assessments, itemized budgets, milestone-based payments, and change-control records.

- Established team: licensed and insured, CalGreen/Title 24 experienced, with detailed bids, schedules, and local references.

Why Local Expertise Matters in the Mountain Climate of Truckee

While building codes are standardized, Truckee's elevation, significant snow loads, and freeze-thaw cycles demand a contractor who knows local conditions and implements them in design and execution. You need a professional who incorporates Snowpack Awareness into structural calculations, determines correct roof pitches, and sizes rafters and connectors for drifting and ice dams. With Microclimate Familiarity, your contractor accounts for shaded lots, canyon winds, and solar gain, choosing materials and assemblies that resist spalling, moisture intrusion, and thermal bridging.

Anticipate precise flashing elements, cold-roof ventilation, heated eave systems, and comprehensive vapor control compliant with Title 24 and local amendments. Appropriate foundation insulation, drainage planes, and air-sealing decrease frost heave risks and preserve finishes. Local expertise leads to fewer callbacks, safer occupancy, and proven durability during Truckee winters.

Design-Build Approach for a Flawless Renovation

With a design-build model, you align architects, engineers, and builders from day one to create a unified planning process that accounts for structural loads, energy codes, and site constraints. You obtain single-point project management that coordinates permitting, schedules, and cost controls, limiting change orders and delays. You copyright code compliance at every step while keeping scope, budget, and timelines visible.

Cohesive Planning Methodology

As seamless remodeling requires coordination beginning on day one, our integrated planning process leverages a true design-build approach—one team translating your vision into buildable plans, precise budgets, and enforceable schedules. We commence with stakeholder coordination: you, our designers, estimators, and trades align scope, priorities, and risk tolerance. Then we confirm site conditions, document utilities, and model structural, mechanical, and envelope constraints to adhere to Truckee and California codes.

We establish phased scheduling that sequences demo work, rough-ins, inspections, and finishing work to decrease downtime and maintain occupancy where practical. Preliminary cost modeling connects specifications to up-to-date pricing, lead times, and permitting windows, eliminating scope drift. Value optimization targets assemblies with the best lifecycle performance. Your approved plans, specs, and budgets become a single, constructible roadmap.

Centralized Project Oversight

Rather than coordinating separate designers, contractors, and inspectors, you get a single accountable lead who owns quality, timeline, budget, website and scope from initial meeting to final walkthrough. Your Project Executive works as your primary contact and decision center, handling design, permitting, procurement, and trade sequencing. You approve one schedule, one budget, and one plan, while we oversee inspections, submittals, and project closeout.

We synchronize drawings with municipal codes, Title 24, wildfire protection standards, and Truckee's snow-load and energy standards. Our Quality Assurance process includes construction feasibility reviews, pre-pour and pre-drywall inspection lists, and recorded inspections. Change management is controlled through documented directives and financial impact records. Risk is mitigated via advance forecasting and reserve tracking. You receive transparent updates, streamlined handoffs, and a reliable, code-compliant remodel.

Kitchen Improvements Created for High-Altitude Living

Within Sierra snow and summer dust, your kitchen needs to perform. You require durable materials, tight building envelopes, and ventilation that handles altitude and wood heat. Start with sealed quartz or sintered stone, Class A fire-rated backsplashes, and induction cooktops to minimize particulates. Specify soft-close, full-overlay cabinets with compact storage solutions—pull-out pantries, toe-kick drawers, and vertical tray dividers—to keep clutter off counters.

Utilize timber accents prudently: kiln-dried, sealed, and positioned per movement requirements. Choose moisture-resistant subfloors, closed-cell foam at rim joists, and heated floors with programmable thermostats. Select ENERGY STAR appliances calibrated for high-elevation performance. Install replacement air for hoods over 400 CFM per IRC M1503, with quiet ECM fans. Layer task, ambient, and under-cabinet LED lighting on dimmers for efficient, glare-free prep.

Bathroom Upgrades That Unite Comfort and Durability

You'll select moisture-resistant materials-cement backing board, epoxy grout, sealed stone, and proper vapor barriers-to withstand Truckee's freeze-thaw and high-humidity cycles. You'll create ergonomic layouts with well-defined ADA-compliant clearances, slip-resistant flooring, well-balanced task and ambient lighting, and properly positioned controls and grab bars. You'll choose low-maintenance finishes such as quartz or porcelain surfaces, PVD-finished fixtures, and high-CFM, code-rated ventilation to reduce upkeep and avoid condensation.

Materials That Resist Moisture

As bathrooms in Truckee experience high humidity and fast temperature fluctuations, choosing moisture-resistant materials isn't optional-it's essential to protect finishes, meet code, and extend service life. Begin with cement backer board and ASTM C920 sealants at all wet junctions. Install silicone based membranes or liquid-applied waterproofing over showers, niche edges, and floor-to-wall junctions, lapped and flashed per manufacturer specs. Choose porcelain tile with low water absorption and epoxy grout to reduce vapor drive. Select PVC, CPVC, or PEX-A supply lines and properly vented fans sized to ASHRAE 62.2. Install pan liners with positive weep protection and slopes of 1/4 inch per foot. Install moisture monitoring sensors behind critical assemblies to catch leaks early and protect framing from concealed damage.

Ergonomic Designs

With moisture issues resolved, layout decisions should support comfort, accessibility, and long-term durability without compromising code. You'll initiate by mapping precise circulation paths: maintain 30 inches minimum in front of fixtures and a 60-inch turning circle when planning universal access. Install toilets 16-18 inches off sidewalls, position grab bar backing now, and align shower controls within easy reach from the entry. Set vanities as space optimized workstations with knee clearance options and anti-tip fastening.

Set reach optimized storage from 15-48 inches above the finished floor to prevent overreaching. Keep towel hooks and GFCI-protected outlets away from wet zones and maintain required clearances from bathtub or shower edges. Favor curbless shower entries with adequately sloped pans, slip-resistant thresholds, and harmonized task, ambient, and code-compliant lighting.

Minimal-Maintenance Finish Solutions

Often overlooked, easy-care surface treatments safeguard your bathroom from everyday use while reducing cleaning time and meeting code. Choose nonporous, stain resistant surfaces like oversized porcelain tiles, quartz, or solid-surface panels for walls and vanity tops; they reduce grout joints and resist mold per IRC ventilation requirements. Choose epoxy or urethane grout for wet zones; it repels staining and will not crumble. Choose maintenance-free hardware: solid-brass, PVD-coated faucets, stainless fasteners, and slow-close, concealed hinges to prevent corrosion. Use factory-finished, moisture-rated baseboards and PVC or composite trim at wet interfaces. Select acrylic or cast-stone shower pans with integral flanges, correctly flashed, and slope floors 1/4 inch per foot to drains. Close penetrations with silicone designed for continuous wet exposure. You'll simplify upkeep and extend service life.

Whole-Home Improvements Delivering All-Season Performance

As seasons shift from Sierra snow to high-desert heat, a carefully planned whole-home renovation offers consistent comfort, efficiency, and durability. Begin with a load calculation and envelope assessment, then right-size seasonal HVAC with zoning, sealed ducts, and balanced ventilation to adhere to Title 24 and IECC standards. We validate R-values, air-seal penetrations, and specify high-performance windows with suitable U-factor and SHGC for Truckee's specific climate zone.

You'll enjoy smart controls that synchronize heating, cooling, and IAQ, plus ductless or ducted systems where they work most effectively. We design electrical capacity, panel schedules, and roof readiness for future solar integration, combined with snow-load framing, roof underlayment, and ice-dam mitigation. To complete the process, we coordinate inspections, permitting, and commissioning to validate everything works safely and to code year-round.

Energy Efficiency and Sustainable Material Choices

Because Truckee's alpine climate demands rigor, you'll prioritize envelope-first efficiency and verified low-embodied-carbon materials from the outset. Commence with an energy model to size systems, right-size overhangs for passive solar control, and document each assembly's carbon intensity. Opt for FSC wood, recycled-content steel, and mineral-based panels with EPDs; prioritize formaldehyde-free, low-VOC products to safeguard indoor air. Validate Green certifications such as FSC, Cradle to Cradle, and Declare to avoid red-list chemicals.

Choose heat-pump HVAC and heat-pump water heaters with cold-climate ratings, and specify smart controls connected to occupancy and weather data. Utilize high-reflectance roofing to limit ice melt variability and lower summer gains. Manage waste with deconstruction and on-site sorting, and source locally to minimize transport emissions. Properly commission systems and maintain documentation for rebates and code compliance.

Cold Weather Protection: Insulation, Windows, and Weatherization

You'll prioritize high-R insulation upgrades that meet Truckee's climate zone regulations and eliminate thermal bridging. Following this, you'll specify Energy Star-certified, low-e, argon-filled window installs with proper U-factor and SHGC for code compliance. To complete, you'll seal openings and drafts with tested air barriers, foam, and weatherstripping to meet target blower-door results and defend against moisture intrusion.

High R Insulation Upgrades

Focus first on your home's most significant heat losses with high-R insulation that complies with or exceeds Truckee's snow-country codes. You'll increase thermal resistance in attics, walls, and crawlspaces while addressing moisture and air leakage. Install R-60+ in the attic with complete air sealing and balanced attic ventilation to eliminate ice dams and condensation. Densely packed cellulose or foam retrofits in wall cavities prevent voids and thermal bypasses. In rim joists, closed-cell foam provides an air, vapor, and thermal barrier in one layer.

Verify assembly U-factors, vapor retarder classes, and fire ratings. Shield combustibles and maintain clearances at flues and recessed fixtures with code-listed covers. Include insulated, gasketed access hatches. Seal penetrations with foam and mastic, then test with blower-door verification to confirm leakage targets and accurate, code-compliant performance.

Energy-Efficient Window Installations

As winter approaches Truckee, select high-performance window systems that align with your climate zone and code path. Choose ENERGY STAR Northern Climate-rated units with NFRC-certified labels. Pursue a whole-unit U-factor ≤ 0.28 and SHGC close to 0.30, modified for your solar exposure. Choose fiberglass or composite frames to minimize thermal bridging and ensure dimensional stability in freeze-thaw cycles.

Utilize double or triple glazing with low-E coatings optimized for winter performance and argon fills for economical thermal resistance. Confirm warm-edge spacers and continuous interior air seals incorporated with the WRB and flashing. Position windows on sloped sills with back dams; use AAMA-approved flashing sequences. Verify egress, tempered glazing near doors and tubs, and correct U-factor documentation for permit approval.

Addressing Gaps and Drafts

Seal the building envelope by carefully sealing the pressure plane where conditioned air leaks most: rim joists, top plates, attic hatches, penetrations, and window/door perimeters. Begin with a blower-door test to target air sealing. At rim joists, use closed-cell spray foam or rigid foam plus sealed seams. Seal top-plate cracks and seal attic hatches with weatherstripping and insulated lids. Foam around plumbing, electrical, and bath-fan penetrations; add fire-rated sealant where codes require. Fix door drafts with adjustable thresholds and continuous bulb weatherstripping. Backer-rod and sealant fill baseboard gaps without trapping moisture. Around windows, use low-expansion foam, interior sealant, and exterior window flashing integrated with WRB per code. Check combustion-air needs and ventilation rates, then retest to confirm leakage reduction and comfort gains.

Financial Planning, Proposals, and Transparent Schedules

Though design decisions set the vision, careful budgeting, strong bids, and transparent timelines maintain your Truckee remodel on track and code-compliant. Commence with a comprehensive scope, room-by-room, including materials, finish levels, contingencies, and allowances. Request cost transparency: line-item estimates, unit costs, and clear exclusions. Request at least three comparable bids with identical scopes to eliminate apples-to-oranges pricing. Confirm labor rates, lead times, and escalation clauses.

Set up phased payments connected to measurable milestones-demonstration complete, rough-ins passed, drywall hung, punch list closed-independent of time. Demand an integrated schedule displaying critical path, long-lead procurement, inspections, and sequencing to preserve adjacent finishes. Review progress on a weekly basis against initial baseline and authorize changes only by means of written change orders with budget and schedule impacts. Hold reserves for seasonal conditions and material volatility.

Building Permits, Regulations, and Collaborating With the Town of Truckee

Before you start hammering in Truckee, outline your project following the Town's permit pathway and the California codes that Truckee implements. Define the scope: structural, electrical, plumbing, mechanical, energy, and defensible space. Verify zoning, setbacks, height, and snow-load requirements. Review local code amendments to the CBC, CRC, CEC, and Title 24 energy standards, including wildfire-urban interface materials and bear-resistant features.

Submit complete plans, structural calcs, CALGreen checklists, and TRPA clearances if applicable. Consult staff about permit timelines, required inspections, and digital submittal formats. Arrange rough, insulation, and final inspections to prevent rework. For older homes, plan for seismic anchorage, egress, and electrical load upgrades. Log any field changes with approved revisions. Have job cards onsite, react promptly to correction notices, and close permits with final approvals.

Selecting the Right Team: Credentials, Portfolios, and Reviews

With permits and code pathways mapped, you must have a team that builds to Truckee's standards without cutting corners. Start by verifying licenses, workers' comp, and liability coverage; ask for policy limits. Focus on certified contractors with ICC familiarity and documented CalGreen, Title 24, and wildland-urban interface experience. Verify they pull permits under their own license and provide stamped plans when needed.

Request project-specific references and recent Visual portfolios that demonstrate structural upgrades, snow-load solutions, air sealing, and defensible-space detailing. Review scope sheets, not just bids—look for specified materials, R-values, fire-rated assemblies, and warranty terms. Examine reviews for schedule adherence, change-order transparency, and inspection pass rates. Finally, interview the superintendent who'll oversee your job; validate communication cadence, site safety protocols, and punch-list closeout process.

Commonly Asked Questions

How Do You Safeguard Pets and Belongings During Construction?

You protect pets and belongings by segregating work zones and managing access. Install pet safe barriers, seal gaps, and place signage. Set up negative air and dust containment according to EPA RRP guidelines. Schedule loud or hazardous tasks when pets are off-site. Use belonging storage: labeled bins, locked cabinets, and off-site vaults for valuables. Protect remaining items with fire-retardant poly, HEPA-vac daily, and preserve clear egress paths to adhere to OSHA and local codes.

What Kind of Warranties Do You Offer on Workmanship and Materials?

Imagine your kitchen remodel: you receive a two-year workmanship guarantee including fit, finish, and code-compliant installation, plus a manufacturer-backed material warranty—typically 10-to-25 years—on cabinets, flooring, and fixtures. You'll get written terms outlining covered defects, response times (usually forty-eight to seventy-two hours), and transferability. We manage registrations, safeguard warranties by observing manufacturer requirements, and document proof-of-installation. If an item malfunctions, we assess, repair, or replace according to contract, giving priority to scope clarity, deadlines, and permit-compliant remedies.

How Are Change Orders Managed and Authorized During the Project?

We record change orders in writing, specify scope, pricing adjustments, and timeline impacts, then obtain your signed approval before any work proceeds. You'll receive an itemized breakdown, updated drawings, and code-compliant specs. We validate feasibility with trades, inspect structural, electrical, and plumbing implications, and update permits as necessary. You approve costs and schedule changes via e-signature. We incorporate the change into the project plan, issue a revised schedule, and track progress transparently.

Do You Supply 3D Renders or Virtual Walk-Throughs Before the Build?

Absolutely-you get 3D renderings and virtual walkthroughs, because trying to imagine wall positions is so 1995. We supply code-compliant 3D visuals that display structural layouts, MEP clearances, fixture locations, and finish schedules. You'll review lighting, sightlines, and ADA clearances, then submit revisions before permits. With Virtual staging, we assess furniture scale, circulation, and storage. You greenlight final models alongside specs, so construction aligns precisely with the documented design-no surprises, just accurate execution.

What Takes Place When There Are Supply Chain Delays?

Should supply chain challenges arise, you'll get an immediate update with modified sequencing and a realistic plan for delayed timelines. We'll propose vetted material substitutions that maintain code compliance, performance, and design intent, documenting changes with specs and approvals. Critical-path items get priority; noncritical tasks shift forward to keep crews productive. We'll secure alternate suppliers, confirm lead times in writing, and update your schedule, budget allowances, and inspections to prevent rework.

Wrapping Up

You want a remodel that manages Truckee's snow loads, freeze-thaw cycles, and wildfire risks-and completes on time. With a design-build team, you'll expedite decisions, control costs, and meet code. For example, a Prosser Lakeview cabin upgrade added R-38 wall insulation, triple-pane U-0.22 windows, WUI-compliant siding, and a heat-pump system; energy bills fell 28% and ice dams disappeared. Check credentials, review portfolios, demand fixed milestones, and confirm permits up front. You'll get durable performance and mountain-ready comfort.